Product Information

CARBON FIBER FABRIC 98 G/M2 PALTTINA

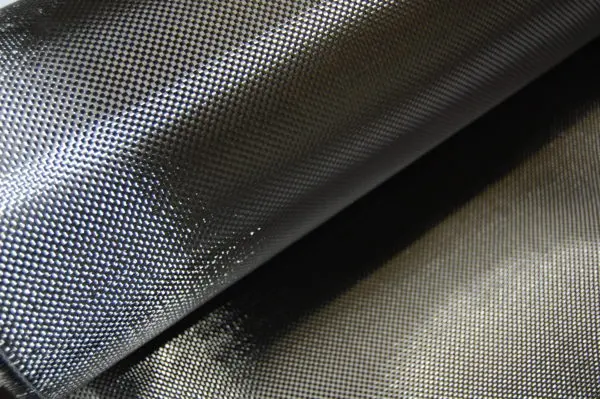

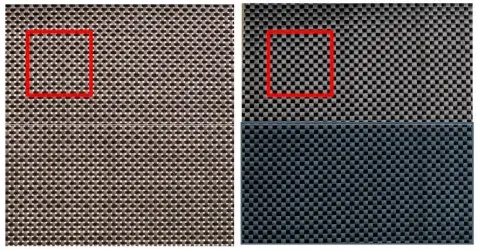

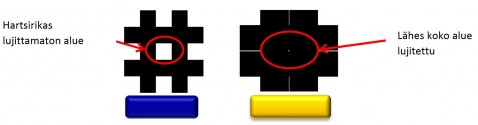

There can be differences between carbon fiber fabrics even if their weight per square meter is the same. For example, in a standard 200 g/m² carbon fiber fabric, individual carbon fibers partially overlap, which affects the fabric’s coverage and the final appearance. In contrast, Hexcel’s Primetex carbon fabric uses flattened carbon fiber tows, where the fibers are laid evenly side by side with minimal overlap. As a result, the weave creates a significantly more uniform and covering surface - without "holes".

Weight: 98g / m2

Width: 1,02 m

Weave: Plain

Tow: 3K

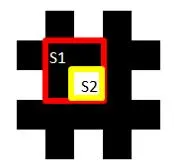

The "openness" of a carbon fiber fabric is measured using the OF value (open factor), which indicates how much of the fabric’s surface consists of empty space between the fibers. For example, Hexcel’s traditional 193 g/m² 3K carbon fabric has an OF value of 7.5%, whereas the equivalent Primetex fabric has an OF value of just 0.5%. Similarly, a traditional 285 g/m² 6K weave has an OF of 3%, while the corresponding Primetex weave again has an OF value of only 0.5%.

The advantages of Primetex compared to standard carbon fiber fabrics are easy to see. When you place your hand or a white sheet of paper behind the fabric, you can observe how smooth and dense the surface is. This type of structure reduces the formation of unreinforced resin areas in the finished laminate, which improves the mechanical properties of the final product. Because Primetex fabrics use flattened fibers, it’s possible to use thicker and more cost-effective tows without compromising the fabric’s uniformity. For example, a high-quality 100 g/m² fabric can be produced using 3K carbon fibers, whereas traditionally 1K fibers would have been required.

Creating a dense and visually uniform carbon fiber laminate is also possible with lighter Primetex fabrics. A 160 g/m² Primetex fabric can offer the same – or even better – coverage than a standard 200 g/m² fabric. For this reason, Primetex is a particularly popular choice for manufacturing automotive tuning parts, where a flawless and striking carbon fiber surface is highly valued.

When using Primetex fabric you achieve excellent mechanical performance combined with a visually appealing carbon fiber surface, with minimal resin pockets – a quality highly valued by users who demand top performance.

Carbon fibers are suitable for reinforcing both thermoset and thermoplastic materials. They are mainly used as reinforcement when the product being manufactured requires a combination of strength, stiffness, and light weight.