KEVYTRAKENTAJAN

VERKKOKAUPPA

Customer Stories

Our products have been used for all kinds of projects – take a look at what our customers have created and get inspired for your own builds!

Do you have a finished project that features Kevra Oy’s products?

Send us your photos at kevra@kevra.fi - We’d love to share your success with others!

Sirpale – Making a Replica

Pekka Rautala has built a replica of the Sirpale boat. No original drawings were available, so the boat was designed using old promotional photos and constructed with a pine strip-plank structure, just like the original. The exterior was laminated with Kevra's epoxy and fiberglass to improve durability. The boat has been showcased at events such as the Vene25 Boat Show and the Puupaattei exhibition in Uusikaupunki.

Custom Front and Rear Fenders

Niilo Valtonen has built custom front and rear fenders for his drifting car. The project used gelcoat, polyester resin, 300 g fiberglass mat, and release wax. The molds were also self-made. The parts have been in use for over five years! Check out more of Niilo's projects on Instagram: @niilovaltonen

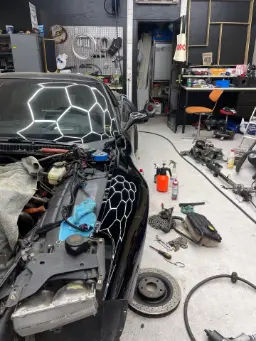

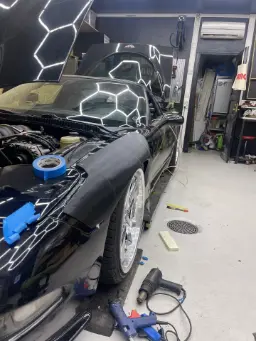

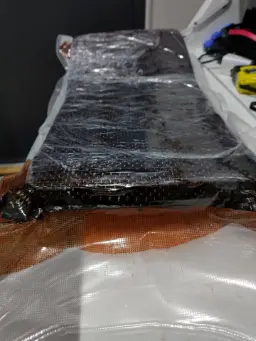

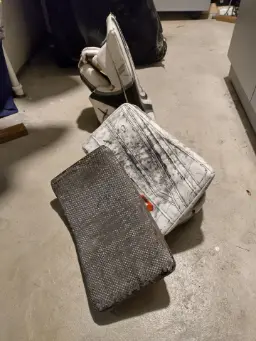

Fender Flares for a Corvette

Miska Kähkönen and his team have designed custom fender flares for a Chevrolet Corvette C5 and created a mold for them. For the mold, they used Kevra’s black gelcoat, polyester resin, air roller, mold release wax, and modeling clay. The final parts were manufactured by JTK Composites Oy. A similar project is already planned for the rear fenders. You can follow the progress on their social media channels!

Instagram/TikTok: @Miskade_vlnt

Youtube: Uncle Send’s.

Wingfoil

Jyrki Haajanen built his own wingfoil board! The board measures 200 x 53 x 15 cm and weighs just 5.6 kg. The core is made from EPS, reinforced with PVC foam sheets. The surface is laminated with 200 g/m² twill carbon fiber fabric and 160 g/m² twill fiberglass. Under the deck padding, there’s also PVC and fiberglass. The final finish is done with 2-component varnish.

Custom Air Deflector

Over the years, Pekka Korhonen has completed several projects using Kevra materials. In his latest build, he created a custom air deflector for a Honda S2000 race car. The unique pattern was made by cutting carbon fiber fabric into small pieces, scattering them in the mold, then pressing in imitation gold leaf, and adding more fiber. For strength, he used plain weave fiber (192 g/m²) and 600 g/m² twill carbon fiber, along with vacuum bagging materials.

Check out more of Pekka’s work on Instagram: @Fin.carbon

Using Carbon Fiber Sheet in a Race Car

Thomas Skjäl used 1 mm thick carbon fiber sheet in his BMW E46 turbo track car.

You can find him on Instagram: @Thomasskjal

Race Boat

He stripped the entire structure and rebuilt everything himself using Kevra materials, reducing the boat’s weight by nearly 80 kg! He’s spent a year fine-tuning the engine and controls. This year, he reinforced and straightened the hull and made components like the steering console, racing seat, and engine cover from carbon fiber. Next up: he’ll be building the fuel tank and throttle pedal also from carbon fiber. Roger has used many of Kevra's products. Here’s a full list of the Kevra's products he used: Fiberglass fabric twill: 160 g/m² and 202 g/m², Fiberglass biaxial: 300 g/m² and 600 g/m², Carbon fiber twill: 202 g/m², Carbon fiber biaxial: 600 g/m² and 800 g/m², Carbon fiber plain weave: 200 g/m², PVC sheets: 3 mm, 5 mm, 10 mm, 20 mm, Ampreg 30 epoxy, microspheres and cellulose fiber, vacuum film, peel ply, and sealant tape.

You can find Roger on Instagram: @soderbacka.racing or @rogge___

Mold Making

Joni Vuorela has created advanced molds for a BMW E21 Group 5 build! The molds were made using 300 g/m² chopped strand mat, polyester resin, and gelcoat, along with release wax. A great example of skilled craftsmanship using simple and cost-effective Kevra materials!

More photos of the project can be found on Instagram: @wss.garage

Carbon Fiber Parts

Seppo Airaksinen has crafted various carbon fiber parts for his supermoto bike. In this project, he made an air filter box using vacuum infusion technique. Materials used: 400 g/m² biaxial carbon fiber, 200 g/m² twill carbon fiber and Ampreg 30 epoxy. The molds were also self-made. Seppo has also built a front fork protector and a skid plate for the bike.

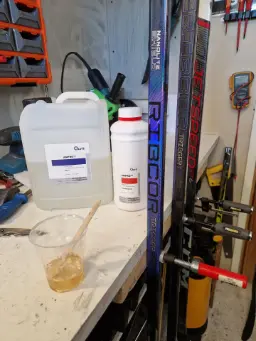

Hockey Stick Repair

Here’s a broken hockey stick repaired by Arvo Taupila using Kevra's carbon fiber sleeve. Thanks for participating in our project competition!