Vacuum bagging using the infusion method

Vacuum infusion is a modern manufacturing method used to produce high-quality composite structures in a controlled and efficient way. The method is based on placing the fiber fabrics dry into the mold and sealing them airtight with vacuum bagging materials. This way, the vacuum pushes the resin through the reinforcement layers. This differs from traditional hand lay-up - the resin is not applied with a brush or roller, but instead flows through the fiber material, drawn by vacuum in a closed system. By using this method, there are virtually no solvent emissions into the workspace, which improves cleanliness and occupational safety.

Vacuum infusion guarantees lightweight, defect-free and accurate laminates with an optimized resin-to-fiber ratio. The method suits perfectly for technically demanding applications, such as the production of composite parts for boats, vehicles, wind turbine blades, as well as the sports and construction industries.

Materials and supplies

The materials and supplies used in vacuum infusion must be carefully selected to ensure the success of the process. The necessary products include, among others:

- Bagging films that are resistant to resins and form the airtight outermost layer

- Peel plies and/or release films that prevent other materials from sticking to the laminate

- Resin flow meshes and channels that ensure even distribution of the resin

- Sealant tapes used to attach the bagging film to the mold and to make the joints airtight

- Hoses, fittings and valves used to control the resin flow and vacuum

- Reinforcement fibers such as fiberglass fabrics, carbon fibers, or hybrid structures

- Resins, such as epoxy, polyester, or vinyl ester resins, with viscosity suitable for vacuum infusion

In addition, a reliable vacuum pump is needed that can maintain sufficient vacuum throughout the entire process, as well as, if necessary, a resin trap and a vacuum gauge.

Process steps

The vacuum infusion process consists of several steps that require careful preparation and the use of appropriate materials. The first step is mold preparation - clean the mold carefully and apply release agent. You can read more detailed instructions for release agent treatment here.

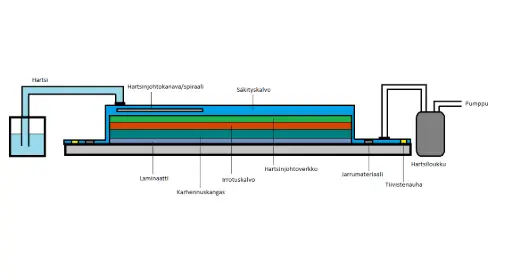

After this, place the dry fiber reinforcements, such as fiberglass, carbon fiber, or aramid fabrics, into the mold.

First, a peel ply, a release film, or both are placed on top of the fibers. If peel ply is used, it should be positioned directly against the fabric. After that, the resin flow mesh is added. These three materials can be used separately, but there are also combination materials , in which they are integrated together on the same roll. By selecting the appropriate resin flow mesh, you can control the resin flow rate within the laminate. In our online store, we offer three different resin flow meshes for sale. OM70 is a plain resin flow mesh, and it transports resin the slowest. The medium-flow resin flow mesh is Infupeel Dianet 135 (a combination of peel ply, release film, and mesh) and the fastest resin flow is provided by Infuplex Flonet (release film and mesh combined).

Depending on the size of the part being produced, resin flow can be enhanced by using various resin distribution channels or spirals. The resin inlet is connected on top of the channel. It is generally a good practice to attach the fitting to the channel in advance before placing the bagging film. This way, the bagging film can be pierced in exactly the right spot with as small a hole as possible.

The resin should not flow out of the laminate toward the vacuum pump—into the vacuum lines, resin trap, and especially not into the pump. Such leakage is prevented by using various brake materials. The brake material stops the leading edge of the resin front and allows time for the slower areas to fill, so the entire fiber-reinforced laminate becomes fully impregnated with resin. These brake materials are characterized by the fact that they stop resin movement but still allow air to pass through. The brake material is placed between the laminate and the vacuum suction line.

The bagging film is carefully sealed to the mold with sealant tape. Remember to add pleats to allow the vacuum bag to stretch to all corners of the mold.

Hoses, fittings, and resin feed lines are connected to the system, and their arrangement affects flow control. The connections between the fittings and hoses are additionally sealed with sealant tape.

When the system is closed, the vacuum pump is is turned on and and it evacuates the air from inside the laminate and the entire structure. The tightness of the bag must always be checked before starting the resin feed. If the bag leaks, the resin will not flow properly and there will be air "bubbles" running into the laminate. Only once the vacuum is stable and the tightness has been verified is the resin released from the container into the laminate. The vacuum draws the resin through the laminate, evenly saturating the fiber material throughout the structure. The progress of the infusion is monitored carefully. Resin flow can be controlled by shut-off valves or by adjusting the number of feed points.

When the resin has infused all the fabrics, the resin inlet is closed. The vacuum needs to be kept on for a longer while. The resin will cure according to the data sheet. After the room temperature cure, postcure is highly recommended.

Advantages of vacuum infusion

One of the most significant advantages of vacuum infusion is the excellent and consistent quality of the final product from part to part. Because the resin is drawn into the fiber layers by vacuum, air is efficiently removed from the system. This prevents air voids or excess resin from remaining in the laminate. As a result, the products are structurally strong yet lightweight.

Because the resin is contained in a closed system, the release of volatile organic compounds (VOC) into the air is minimal. The work environment remains cleaner, and working comfort is significantly improved compared to open lamination methods.

Material efficiency is also a significant advantage. Only the exact amount of resin needed is used, and no excess is wasted. This reduces material costs, improves repeatability, and simplifies quality control.

It is important to note that successful vacuum infusion requires good planning, testing, and practice. We recommend trying the process first on a small scale.