Core Materials – Lightweight Structures, High Performance

Core materials are an essential part of sandwich-structured composites, where the goal is to combine light weight with excellent mechanical durability. The core is placed between two reinforced laminates, significantly increasing the stiffness of the structure without adding much weight. This makes them an ideal choice for applications such as boat building, transportation, construction panels, and wind turbine components.

Gurit® – Ydinaineet

Core materials are an essential part of sandwich-structured composites, where the goal is to combine light weight with excellent mechanical durability. The core is placed between two reinforced laminates, significantly increasing the stiffness of the structure without adding much weight. This makes them an ideal choice for applications such as boat building, transportation, construction panels, and wind turbine components.

Recommended storage temperature: 10 – 30 °C and relative humidity below 70%. Avoid direct sunlight.

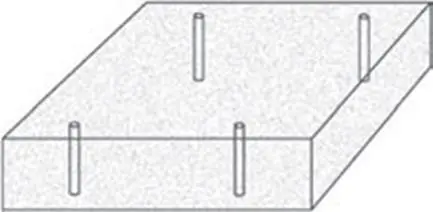

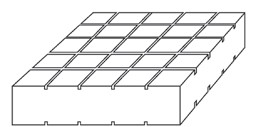

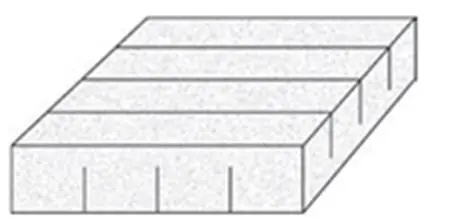

PH-PLAIN PH-PLAIN / perforated VIC CUT- Vacuum Infusion Version

Cuts

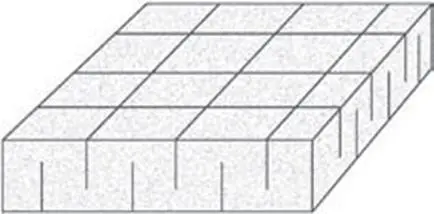

Composite structures are typically not flat, so core materials must conform to the shape of the structure. This can be achieved through thermoforming or longitudinal cuts. Additionally, cuts help air movement and resin flow in vacuum infusion processes.

SC- Single CUT DC- Double CUT CS- Grid Scored

Typical Properties of Core Materials

Density kg/m³ | Compressive Strength MPa | Compressive Modulus MPa | Tensile Strength MPa | Elongation at Break %

| Shear Strength MPa | Shear Modulus MPa | Thermal Resistance °C | |

Polystyrene | 28–48 | 0,2–0,4 | 0,2–0,4 | 0,006–0,011 | ||||

Polyurethane | 32–320 | 0,2–5,9 | 0,1–3,1 | 1–103 | 135–150 | |||

PVC | 40–250 | 0,52–6,88 | 29–296 | 0,71–7,19 | 6–35 | 0,47–4,37 | 15–98 | |

Corecell M (SAN) | 60–200 | 0,55–4,4 | 12–317 | 20–53 | 0,68–2,95 | 20–98 | ||

PMI | 32–200 | 0,4–15,8 | 1,9–3,5 | 0,4–2,4 | 13–50 | 180–250 |

Thermoforming

In thermoforming, the panel is shaped using heat. Gurit’s Corecell and PVC cores are thermoformable. Recommended temperatures for each material are shown in the table below. Exceeding the maximum temperature may soften the core material.

Process:

1. Heating

2. Forming

3. Post-forming

| Thermoforming temperature (°C) | Thermoforming temperature (°C) | |

Type | Product | Recommended | Maximum temperature |

Gurit® Corecell™ SAN (styrene acrylonitrile) | M | 110 | 120 |

Gurit® PVC (polyvinyl chloride) | PVC | 120 | 135 |

PVC HT | 140 | 155 | |

Kerdyn™ Green | PET | 140 | 160 |

Hand Lamination & Infusion

All core materials are porous. The lower the density and the larger the cell structure, the more resin will be consumed. Excess resin consumption also depends on the manufacturing technique.

Prepreg/Sprint

Each core material has a maximum temperature limit, after which mechanical properties begin to degrade.

Type | Product | Typical Process Temperature Limit |

Gurit® Corecell™ SAN (styrene acrylonitrile) | M | 120ºC for 1 h |

Gurit® PVC (polyvinyl chloride) | PVC | Not recommended for prepreg processing |

PVC HT | 120ºC for 1 h |

Main Core Material Types

PVC Foam Sheets

PVC core material is now one of the standard raw materials in boat building and repair. The sheets are ideal for applications requiring low weight and high strength – particularly in boats where excellent fatigue strength and minimal water absorption are important. PVC foam is compatible with all common resin systems.

Properties:

- Excellent chemical resistance

- Self-extinguishing

- Suitable for all sandwich structures

PET Foam Sheets

- Gurit® Kerdyn™ Green Core Material: Made from 100% recycled material

- High processing temperature

- Excellent chemical resistance

- Good adhesion and mechanical properties

- Recyclable

- Low resin uptake

SphereCel Core Mat

A filled core mat for sandwich constructions.

SphereCel core mats are made from fiberglass fabric and microspheres. They are used when thickness and stiffness need to be quickly added to a composite structure. Typically used in a few millimeter thicknesses, SphereCel can be applied to flat or contoured laminates. Its use can reduce laminate weight by up to 40–60% compared to chopped strand mat.

Balsa Wood

A natural and extremely strong core material with high compressive and shear strength. Particularly suitable for demanding load conditions and moist environments.

We stock a wide range of panel sizes. If you're interested, please contact us directly at kevra@kevra.fi or 09 6126820 and we’ll be happy to assist you.

More Information

Structural Core Processing Guide