Product Description

Ecoflex 00-30 7,26 kg

Ecoflex™ silicones are platinum-cured, addition-cure silicones mixed in a 1A:1B ratio by weight or volume. They cure at room temperature with minimal shrinkage, making them an excellent choice for molding and casting soft, flexible components.

Their low viscosity ensures easy mixing and helps reduce air entrapment. Once cured, the silicone is exceptionally soft, strong, and stretchable. It can be stretched multiple times its original length without tearing and will return to its original shape without deformation.

Ecoflex™ 00-30 is certified skin-safe by an independent laborator.

Properties

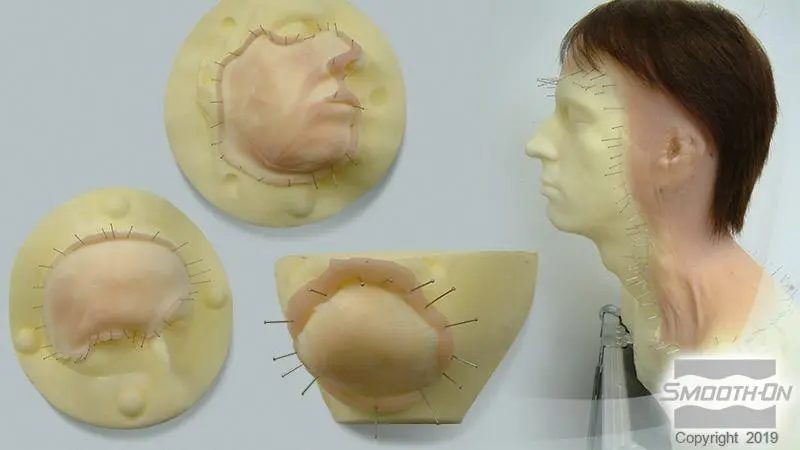

- Translucent appearance, can be pigmented with Silc Pig™ colors for customized effects

- Compatible with THI-VEX™ thickener for brush-on applicationst

- Ideal for creating prosthetic appliances, cushioning in orthotics, and special effects – especially in applications requiring repeated motion, such as animatronics

Hardness (ShoreA) | < 0 |

Mixing ratio (by volume) | 1:1 |

Pot life (23 °C) | 45 min |

Curing time (23 °C) | 4 h |

Heat resistance (min) | -53 °C |

Heat resistance (max) | 232 °C |

Shrinkage | <0.0254 mm/mm |

Viscosity (cpc) | 3000 |

Elongation (%) | 900 |

Color | Translusent |

Instructions for use

Before starting, stir both components thoroughly as some settling may occur during storage. Measure Part A and Part B in a 1:1 ratio by weight or volume. Mix for at least 3 minutes, ensuring the sides and bottom of the container are scraped to prevent unmixed material and uneven curing.

For best results, vacuum degassing is recommended after mixing. Use a vacuum pump capable of pulling at least 1 bar (100 kPa). Leave room in the container for expansion – the silicone will rise, break, and fall. Continue vacuuming for one more minute after the silicone has settled.

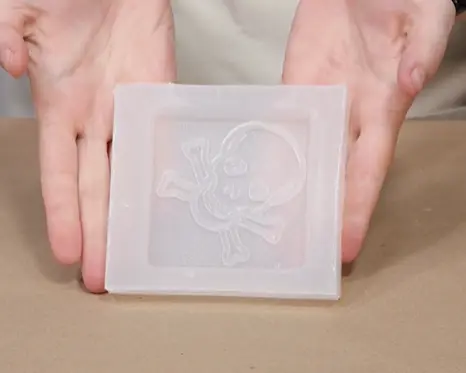

Pour the silicone slowly into the lowest point of the mold and let it flow naturally to cover the model. This helps minimize air bubbles and ensures a smooth surface. When making a one-piece mold, ensure the silicone covers the model by at least 1 cm above its highest point.

Let the silicone cure at room temperature (23 °C). Avoid curing below 18 °C, as the reaction may slow down or stop entirely. Optional post-cure: Cure the mold in an oven at 80 °C for 2 hours, followed by 100 °C for 1 hour. Allow it to cool to room temperature before use.

Cure Inhibition: Ecoflex™ may not cure properly if in contact with certain materials, such as latex, tin-cure silicones, sulfur-based clays, certain woods, fresh polyester, epoxy, or polyurethane. If unsure, test compatibility on a small, non-critical area. Signs of inhibition include tacky or uncured areas after full cure time. Coating the model with a clear acrylic lacquer can help prevent cure inhibition. Allow the sealer to dry completely before applying silicone. Note: Platinum silicones will not cure properly on sulfur-rich clays, even with a sealer. Always test before full use.

Mold Use & Storage

Fresh silicone molds naturally release most cast materials. However, repeated casting – especially with resins – may reduce mold performance over time. No release agent is needed for wax or plaster. When casting polyurethane, polyester, or epoxy resins, a release agent such as Ease Release™ 200 is strongly recommended to protect the mold.

Clean molds with mild soap and water and dry thoroughly before storing. Assemble multi-part molds during storage. Store molds on a flat surface in a cool, dry place away from direct sunlight..

Modifying Viscosity

- Use THI-VEX™ to increase the viscosity of Ecoflex™ silicones for brushable applications. Adjust the amount to achieve the desired consistency.

- Silicone Thinner™ reduces viscosity for easier pouring and degassing. Note that adding thinner will reduce tensile strength and tear resistance. Do not exceed 10% of total mix weight.

Safety

Work in a well-ventilated area. Wear safety glasses, long sleeves, and only vinyl gloves (latex gloves will inhibit cure). Store and use materials at room temperature (~23 °C). Elevated temperatures will reduce working and curing time and shorten shelf life. These materials have a limited shelf life and should be used as soon as possible after opening.