Glass fiber

Currently, most fiberglass (or glass fiber) on the market (approximately 99%) is made from E-glass, which is recognized for its reliable electrical and mechanical properties as well as its chemical resistance. The fiberglass products in our selection are primarily made from E-glass.

The primary function of reinforcements is to carry the loads applied to a composite structure. The matrix resin binds the reinforcements together, protects them, and transfers the load to the fibers. While the mechanical properties of the resin can be improved with fillers or additives, true reinforcement relies on fibers specifically designed for this purpose.

The largest user of fiberglass is the fiber-reinforced plastics industry, where it is used, among other forms, as yarn (spray-up and filament-winding yarn), chopped strand mat, woven roving fabric, multiaxial fabric, braid, and felt (usually C-glass). For example, in the boatbuilding industry fiberglass is often used as spray-up roving together with polyester resin, or as hand-laminated fiberglass mat. In addition, fiberglass is used in the manufacture of fabrics and similar products, and in the form of glass felt as a reinforcing/carrier material in bituminous roofing membranes and in PVC floor coverings and wallpapers. More information on fiberglass can be found at lujitemuovi.fi website.

Reinforcements are used to enhance the mechanical properties of plastics. When selecting glass fiber fabrics, the first step is to determine the required strength of the final component.

For example, a waterproof surface can be achieved by using 160 g/m² twill glass fiber fabric with epoxy. In repair applications, the most commonly used materials include chopped strand mats, glass fiber fabrics, and multiaxial fabrics. However, chopped strand mat should not be used with epoxy resin.

Glass fiber fabrics

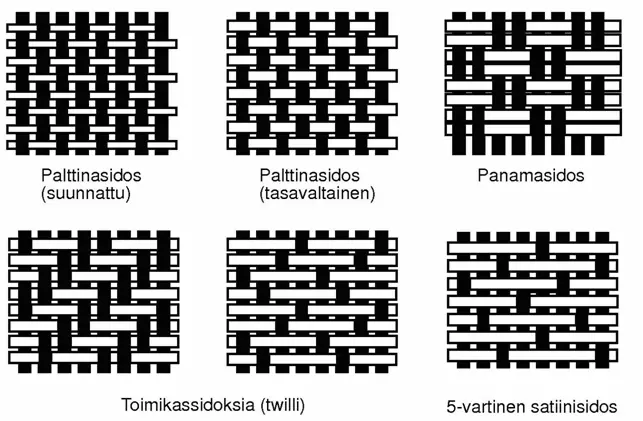

Glass fiber fabrics are woven and can be either balanced or oriented. Common weave types include plain, twill, and satin. The weight and width of the fabric are selected according to the application. Plain weave is stable and easy to handle, twill conforms better to curved surfaces, and satin provides a smooth surface finish. Lighter fabrics are suitable for thin components requiring precise surface detail, while heavier weaves offer better structural strength.

Biaxial and multiaxial fabrics

In biaxial and multiaxial fabrics, parallel, side-by-side glass fiber yarns are stitched together in layers. The layers are typically oriented at +45°/-45° or 0°/90° angles in the roll direction. Multiaxial fabrics contain more than two layers (usually three or four). One of the key advantages of this structure is that the reinforcement fibers are positioned straight (which is mechanically efficient), and the layers can be oriented in desired directions. A chopped strand layer can also be added to the yarn or fiber bundle layers. This structure allows for various combinations and the use of different reinforcement fibers within the same product.

Chopped strand mats

Chopped strand mats (CSM) consist of approximately 50 mm long chopped glass fiber strands, held together with either an emulsion or powder binder. They are mechanically weaker than woven fabrics, so achieving equivalent strength requires a thicker layer. Additionally, they absorb more resin, resulting in a lower fiber content in the final structure. The chopped strand mats in our product portfolio are emulsion-bound and are suitable for use with polyester resins.